© 2024 All rights reserved

Project by UsedTextilemachines.eu

Don't have an account yet? Register

Do you already have an account? Go to login Click here

Don't have an account yet? Register

Do you already have an account? Go to login Click here

Looking for the best opportunities to satisfy the customer:

Mobile Phone: +393319020189

Working hours: 09.30 / 12.30 - 16.00 / 18.00 From Monday to Friday.

Topping is a process that involves cutting and homogenizing the surface pile of the fabric

at a certain height. It is normally carried out dry and on almost all fabrics. His

intensity varies from complete cutting of the superficial filaments to a simple trimming of the

their ends.

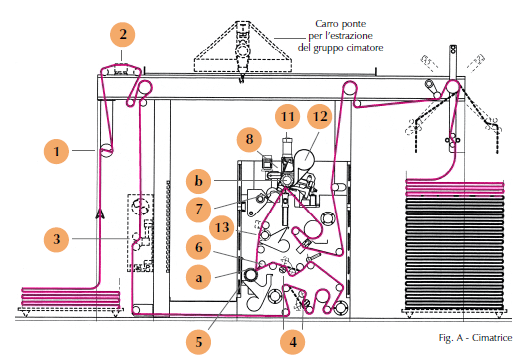

The fabric passes in succession, through a tensioner (see figure A, point 1), a metal detector

(fig. A, 2) and a center piece (fig. A, 3), driven by cylinders, some in neutral and others controlled. Two

spreading cylinders (fig. A, 4), stretch the pieces perfectly and avoid creases and swelling

before logging in

at the velvety point (fig. A, a), where they are found

a cylindrical brush (fig. A, 5) with adjustable speed, which straightens the hair with steel points

flexible, and

a movable wedge bar (fig. A, 6), which controls the approach of the fabric to the brush and to the cutting point (fig. A, b) where

a metal cloth holder (figs. A and B, 7), also wedge-shaped, keeps the fabric taut close to the unit

trimmer, whose distance from the fabric, adjustable, determines the length of the pile.

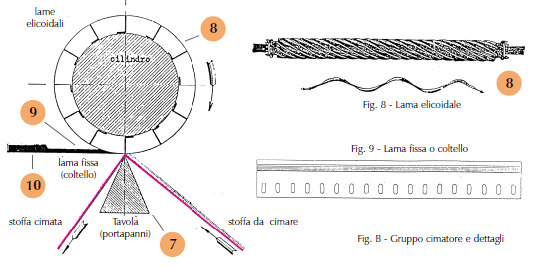

The trimming group (fig. B) which is the most important part of the trimming machine, consists of:

a rotating trimming cylinder (figs. A and B, 8 and fig. 8, detail), called male, which depending on

of its diameter, it can accommodate from 16 to 32 helical blades of tempered steel placed on it

it to screw;

an adjustable blade, called a knife (fig. B, 9 and fig. 9, detail), as long as the cylinder and locked

on the special support (fig. B, 10).

The helical blades of the trimming cylinder, in contact with the underlying fixed blade (knife) create

a contrasting cut point of the hair. When the trimming cylinder has completed its turn, the blade

with a helix attached to it, he cut the hair from one selvedge to the other. Helical blades can be

wound on the cylinder from right to left or vice versa. The direction of the propellers on multi-cylinder trimmers

it is alternated to avoid deviations of the piece and stabilize it in the center.

The fluff produced by the topping is removed by a vacuum cleaner (fig. A, 12).

A pneumatic lifter (fig. A, 11) intervenes at the passage of the seam at the end of the piece.

In addition to the velvet machine and topping groups, there are:

hair-coated brushes (fig. A, 13); particularly important is the one placed before the group

trimmer which, acting on the reverse side, removes any threads or fibers from the surface of the fabric;

feelers, which operate the lifting of the cylinders when the seams pass wide;

a thick felt soaked in a special oil that rests on the trimming cylinder, which keeps the helical threads and the fixed blade efficient for longer;

a series of dragging cylinders, which carry the pieces to the folding machine.

The trimmer configurations can include: 1) single machine; 2) multiple machines online; 3)

machines arranged on a chain of different processes (for example raising and topping).

The trimmer must:

start the machine, to check the direction of rotation and the contact of the brushes with

tissue;

introduce the fabric, prepared according to the desired result and sewn into a ring;

lower the cylinder when the fabric arrives at the trimmer unit, adjusting its height with the screws

register.

Then check:

• uniformity of contact and thickness between the piece and the blade, stopping the machine and making it slide

paper thicknesses over the entire working height (usually made up of one or more tags).

• The felt placed over the cylinder, checking that it is soaked in the right quantity of oil.

Start the topping and at each complete turn of the piece

• compare the height of the topping, with the sample,

• lower the cylinder, proceeding for successive cuts until the desired result is obtained.

More or less large holes deriving from knots not previously cut, shells or balls of fluff

formed on the reverse and not removed by the brush, especially on combed to be shaved a

bottom.

Irregular shaving that occurs due to folds, overlapping of the fabric or lumps on the back.

These are the same causes as holes, but with a higher cylinder treatment.

Difference between center and selvedge, caused by not well-level preparation of the gauze or dal

cloth holder.

Cut for the length of the piece, for foreign material fixed on the cloth holder that lifts the fabric.

Hair cut not clean and uniform due to lack of cutting of the group.

By moving the fixed blade with respect to the cylinder, you can increase the cut but once you have reached the limit of movement,

the cut does not improve so the group must be sent to the workshop to be rectified and ground.

The trimmer, in addition to the set tasks, must perceive "with the ear" sounds different from normal

topping, as carelessness of a few minutes can divide a patch.

The machine is equipped with accident prevention sensors, but it is necessary to pay attention to where you put them

hands with sensors disconnected. Cleaning must always be carried out with the machine stopped and in any case

very carefully to the blades.

After the sale of the machinery we also assist you in logistics and if desired by the customer we have technicians capable of reassembling and starting the machinery.

© 2024 All rights reserved

Project by UsedTextilemachines.eu

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Fill out the form to contact me