© 2024 All rights reserved

Project by UsedTextilemachines.eu

Do you already have an account? Go to login Click here

Do you already have an account? Go to login Click here

Looking for the best opportunities to satisfy the customer:

Mobile Phone: +393319020189

Working hours: 09.30 / 12.30 - 16.00 / 18.00 From Monday to Friday.

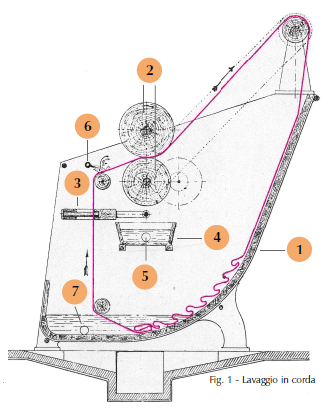

The machine consists of:

a) a deep tank, which contains the degreasing solution,

(see figure A, point 1).

b) On the tank there are two squeezing cylinders (fig. A, 2),

adjustable pressure,

c) a rack device (fig. A, 3),

that separates and guides the pieces, blocking

processing at the passage of any

knots of fabric (which raise it).

d) Under the squeezing cylinders

a basin (fig. A, 4) recovers

the emulsion squeezed out of the fabric.

e) A coil heats the bathroom.

f) A tube starts from the basin

drain (fig. A, 5),

closed at certain stages of the process.

g) A series of nozzles (fig. A, 6),

for the introduction of water

in the tub.

h) A drain valve,

at the base of the tank (fig. A, 7).

i) In front and at the top, outside the machine, a cylinder unloads the washed pieces.

j) A control panel allows you to set the parameters and manage the machining.

The purgator must:

insert the pieces (normally sack-sewn) under the two squeezing cylinders and slide them between

of them until the head reaches the foot of the rack.

Pass the head of each piece of the tub from the rack and sew it evenly with the tail, for

form a ring.

Be careful not to wrap the piece up before sewing it.

Adjust according to the type of fabric to be treated (with diligence and great attention):

pressure of the cylinders - temperature of the bath - introduction of water, solvents and any products

auxiliaries - toilet and basin drains.

The transition from degreasing to rinsing is very important: it must be done gradually for

allow an effective expulsion of the emulsion and all the impurities it contains.

Incorrect washing can compromise subsequent operations and the quality of the fabric: it is therefore

It is important that the same or at least compatible pieces are treated in the same processing cycle

by color and characteristics of the fabric (weight, composition, etc.).

An improper wash can cause beating on particular types of fabrics.

Badly performed degreasing:

jeopardizes a regular uniformity of dyeing;

gives a bad smell to the finished fabric;

compromises the brilliance of colors on patterned fabrics.

The purgator, for his own safety, must make sure that the floor is not slippery.

He must then, also on the basis of his own professional experience, make choices and checks such as:

times of the various processing stages,

cylinder pressure adjustment,

respect the indicated percentages of solvents and auxiliary products,

check the regular flow of the pieces,

check the degree of degreasing at the end of the wash.

After the sale of the machinery we also assist you in logistics and if desired by the customer we have technicians capable of reassembling and starting the machinery.

© 2024 All rights reserved

Project by UsedTextilemachines.eu

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Fill out the form to contact me